Description of the technology

After two successful pilot campaigns at industrial scale, the technology was installed in one of AGC Glass Europe Float glass furnaces.

Temperatures and fluid flow rates were tracked to optimize fuel consumption at each step of the project and to evaluate the technology’s efficiency. The first results, whether for cold reactants or hot reactants, were very promising. Compared with air firing, NOx emissions were reduced by minimum 75% and energy consumption was decreased to the targeted 25%. Despite the technical challenge involved, the furnace efficiently produces good glass since the start-up.

After several years of fruitful collaboration, AGC Glass Europe and Air Liquide are continuing to develop breakthrough technologies for efficient glass manufacturing, focusing on adapted solutions that adhere to local legislation and respect the environment in addition to benefiting their customers.

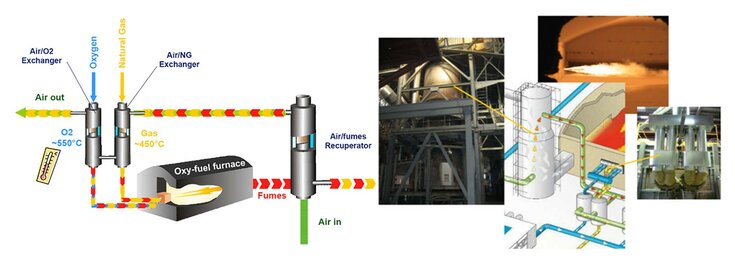

Air Liquide and glassmaker AGC Glass Europe have developed ALGLASS™ Heat Recovery to recover most of lost heat by indirectly preheating fuel and oxygen. It is the only current oxy-fuel technology to take advantage of this wasted energy for improving the combustion. ALGLASS™ Heat Recovery is a set of technologies specifically designed and approved for safety and reliability. Among them is the ALGLASS SUN, a new-concept burner with staged combustion, which can accommodate reactants at either ambient or very high temperatures.

LIFE+ Programme

This project is funded by the European Commission within the LIFE+ Programme